G

eothermal energy can pro-

vide clean, renewable, basel-

oad electricity, but it has its

challenges. Upfront project costs

are high due to the need to drill and

explore potential sources and, in

some parts of the world, projects

can be subject to lengthy permitting

periods. In the US, for example, it

can take up to seven years to obtain

the necessary permits for a geother-

mal project. This long permitting

time delays the start of energy pro-

duction and adds to the overall cost

of the project.

The technology is also limited by

geography. Geothermal resources

are often located in specic regions

with high geothermal activity, such

as Iceland, Indonesia, the Philip-

pines, and specic locations in the

western United States.

Consequently, uptake has been lim-

ited. According to the International

Energy Agency’s most recent report

on the sector, geothermal meets less

than 1 per cent of global energy de-

mand and its use is concentrated in a

few countries with easily accessible

and high-quality resources. It says,

however, that with continued tech-

nology improvements and reductions

in project costs, geothermal could

meet up to 15 per cent of global

electricity demand growth to 2050.

This would mean the cost-effective

deployment of as much as 800 GW

of geothermal power capacity world-

wide, producing almost 6000 TWh

annually, i.e., equivalent to the cur-

rent electricity demand today of the

US and India combined.

In recent years there have been

several innovations that could go

some way to making this possible,

one of the most interesting being

one from Geothermal Gradient. The

US-based company has developed

an innovative system that is bring-

ing geothermal energy to the oil and

gas sector, with the potential to also

power the rapid global expansion of

data centres.

Known as the HXC system, it is

essentially a system that conveys

heat from generally dirty wastewa-

ter sources for use in an organic

Rankine cycle (ORC) for power

generation.

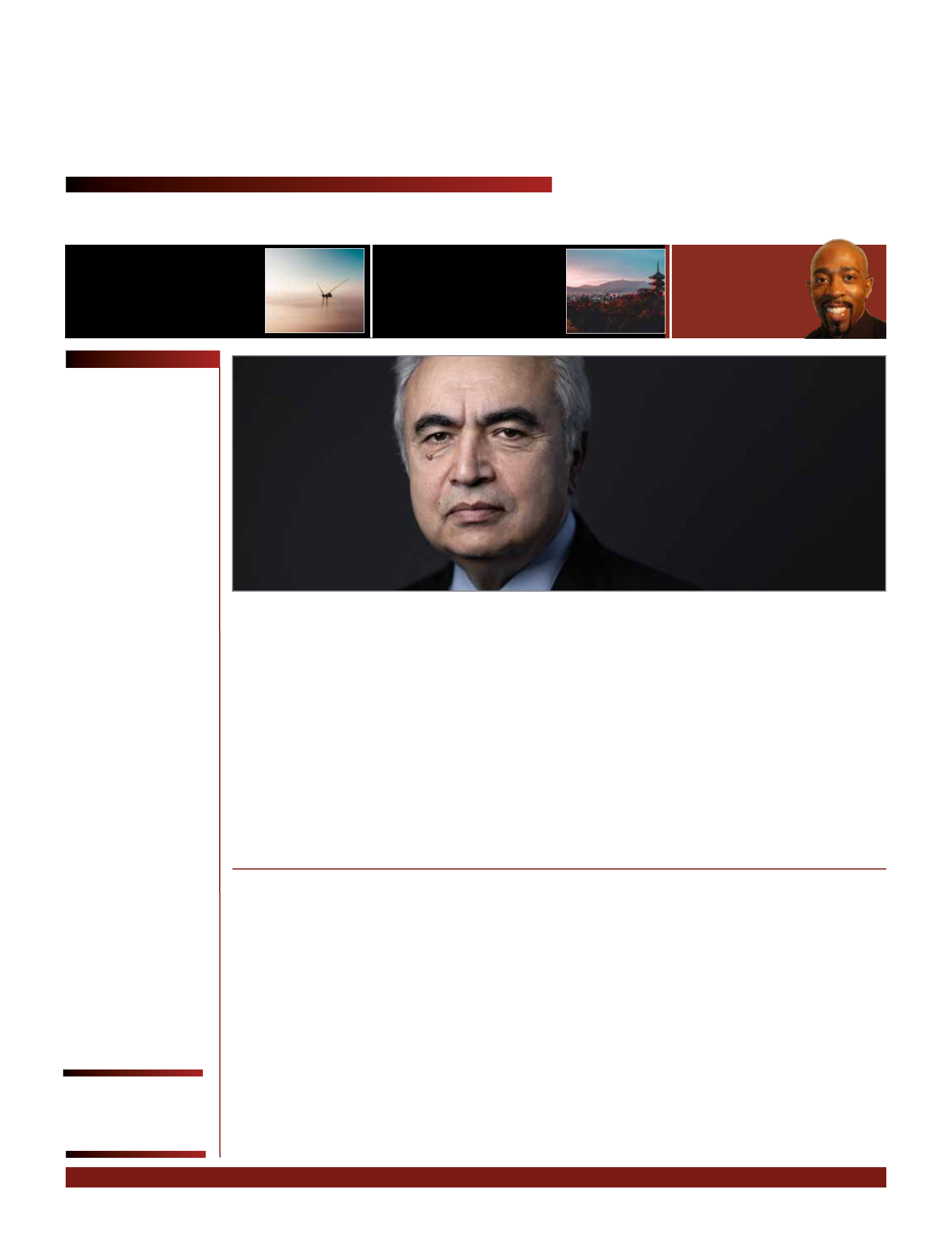

Benjamin Burke, CEO of Geother-

mal Gradient, explained the roots of

technology. “The whole idea, for this

started with my previous work in the

oil and gas industry as a geoscientist,

and seeing the opportunity that was

all around the industry, in the form

of heat waste. Fluids were constantly

being produced and cooling off on

the surface… I realised there was an

opportunity in the thermal side of

water and that’s where the spark for

the company really came from.

“I was one of the company’s co-

founders in 2020. The HXC system

itself came from the need to connect

ORC units to oil and gas facilities…

We needed to convey heat from a

generally dirty uid stream, some-

thing that certainly contains scale,

oil, gas, high brine content, and in

some cases rags and plug parts. But

we needed to convey just the heat to

the ORCs and most ORCs require

very clean water. That’s where the

idea of the HXC came from.”

The system has two key compo-

nents. One is the HXC sled to con-

vey heat from a produced uid

stream to the ORC. The second sled

is the ORC itself, and Geothermal

Gradient is able to adapt any off-the-

shelf ORC to work with a dry air

cooler.

“It’s a water-free cooling mecha-

nism, which has water in its loops,

but doesn’t consume any water, said

Burke. “The two units can come off

a lorry or truck and be installed in

one day. And we can do that in any

rural location in the world.”

He notes that the same sled con-

cept can really be used in a number

of ways. The company has in fact

had a good amount of interest from

oil and gas operators all over the

world.

The units are also sized so they

can be installed as small modules,

according to the operator’s needs.

Each sled can produce anything

from 75 kW to 300 kW using differ-

ent sized ORC generators.

“The modularity is what our cli-

ents really like about it,” said

Burke. “Along with that ease and

quick installation, we have the mo-

bility. So, if an oil and gas well site

only ows the right amount of uid

for a year or two, the modularity

means that we can move it on to the

next site.”

he system needs uid at a tem-

perature of at least 70-75°C to oper-

ate, and 2000 barrels/day to make a

reasonable amount of power. “The

more the merrier in terms of both

temperature and uid ow, to get

more power,” noted Burke.

A handful of projects have already

been completed or are underway in

the oil and gas sector and more are

on the way. Geothermal Gradient’s

rst system was at a pilot proect in

Nevada, in the western United

tates, while its rst commercial in-

stallation is with an oil and gas op-

erator in the Williston Basin in

western North Dakota. The second

commercial project is due to start

up this month (May) in western

Louisiana.

Burke added: “We’re very excited

to work on a project in Argentina,

which will hopefully be kicking off

later this calendar year, as a well as

a proect in man at a steam ood

eld.”

The technology is now also gar-

nering interest from geothermal op-

erators and data centre operators.

urke explained: eve had ve

different geothermal operators ap-

proach us in the last four months…

Some geothermal operators are op-

erating and drilling, and planning to

have larger facilities. Our equip-

ment can help them to get to rst

electrons very quickly and test

some of their wells. They are look-

ing to use us, while their large more

bespoke multi-megawatt power

units are in construction.”

But it is the growth of data cen-

tres, driven y the advance of arti-

cial intelligence, that makes the fu-

ture even more exciting. The HXC

system is well suited for deploy-

ment at liquid-cooled data centres.

These data centres typically have

processors sitting in a bath of water

or some form of refrigerant. This

heat from the processors is pumped

outside the building, usually to a

uid chiller and cooled off.

“Our equipment, in making pow-

er, can act as that uid chiller,” said

Burke. “Additionally, we can use

ground loops – just like a thermal

energy network or a district heating

network would have a ground loop

for rejecting heat to the subsurface.

So, a data centre is essentially a

building with a pipe of hot water

coming out of it, which to our

equipment looks a lot like an oil

and gas well and we can cool that

uid stream ust as we could cool

an oil and gas well.

According to Burke, the company

has received “a lot of initial excite-

ment” over the idea of a water-free

solution for data centre cooling. This

is important since many of the exist-

ing cooling solutions for water-

cooled data centres involve some

type of misting, or evaporative cool-

ing, which can be a problem in parts

of the world where water is scarce.

According to Burke, the econom-

ics of the technology also stack up

well, versus current solutions. This

he says, goes hand-in-hand with

emissions savings of about 0.5 kg

(1 lb) of CO

2

for every kWh, when

compared with savings against the

grid. This roughly doubles for die-

sel installations.

Geothermal Gradient has initially

adopted a lease model for HXC,

which is well suited to the modulari-

ty of the system.

Burke noted: “Although we cer-

tainly can sell the units, we’ve start-

ed as a leasing model because a lot

of oil and gas operators tend not to

own the heavy equipment that they

use – they tend to lease the drill rigs

and a lot of equipment that goes onto

a site. So, the idea of leasing our

geothermal euipment ts very

cleanly with their business model.”

The lease approach also makes

HXC cost competitive with existing

solutions. “In leasing these units,

[compared to] the incumbent solu-

tion that we are replacing, we are es-

sentially one-to-one or slightly less

expensive than the amortisation cost

of the uid chillers that operators

currently use,” said Burke. “Plus,

they get power [from the HXC sys-

tem], as opposed to pulling power

from the grid. Or even worse, from

an emissions standpoint, using diesel

generation for the power. Compared

to the incumbent solutions there is

about a 10-20 per cent [cost] saving

for oil and gas operators.”

He explained that a one-off solu-

tion for a client is not the most cost-

effective option but noted: “At a full

build-out we’re on the order of 8-11

cents/kWh, when power generation

is the goal.” Burke added: “If heat

rejection is the goal – for a lot of our

clients, uid chilling is the primary

goal – whatever they get from that is

secondary. So there, you have to

equate the cooling duty of the solu-

tion along with the kilowatt hours of

electricity produced, and you still

end up with about the same num-

ber… that’s a very competitive num-

ber for a baseload power solution.”

As long as water is owing, day or

night HXC can make power and pro-

vide cooling duty. With a capacity

factor above 90 per cent, this com-

pares very favourably with solar at

20-25 per cent or wind at 30-40 per

cent. “When this capacity factor is

normalised against the levelised cost

of energy, we’re as cheap as wind

and solar, if not more so,” said

Burke.

The technology certainly has a

bright future. As Burke summed up:

“We’re really excited about the op-

portunities to take advantage of ther-

mal resources that are being pro-

duced every day and have that

advantage work for our clients, work

for ourselves, and in some cases

work for public entities where the

wells are in the public domain. It’s

been gratifying to see that interest

truly worldwide in the uptake of our

technology.”

A new technology

developed by

Geothermal Gradient

col reene the

geothermal energy

landscape. Having

demonstrated the

ability to convert

waste heat from

existing oil and

gas operations into

renewable power

without the need

for any new drilling,

this modular, mobile

system also has

the potential to help

satisfy the needs

of the fast-growing,

power-hungry data

centre market.

Junior Isles explains.

Modular geothermal opens new

Modular geothermal opens new

opportunities

opportunities

THE ENERGY INDUSTRY TIMES - MAY 2025

15

Technology Focus

Geothermal Gradient has

oleted ts rst oeral

installation at a Chord Energy

well-pad in North Dakota, USA