of multiple gas red boilers that gen-

erate steam for the facility; among

them are two steam turbine-compres-

sor trains. The rst train consists of a

25 MW steam turbine driving a com-

pressor, and a second train with an 8

MW steam turbine and compressor.

“Basically, it’s two electrications

in one project,” said uyderduyn.

“So, we are replacing two steam tur-

bines with two electric motors. The

steam turbines are still running well.

They had some overhauls but now is

a good time to take them out.”

Postma added: “The steam turbines

have been running continuously

without any stops. And replacing

them is a challenge. If you move to

electrically-driven motors, you have

to ensure that they can run 247 for

35 daysyear for decades, at least

until the next turnaround, without

failure.

Siemens Energy, together with

Shell, carried out a reliability, avail-

ability and maintenance (RAM) study

during the tender phase and are con-

tinuing this study during execution to

identify any weak spots.

“This helps us select the right mate-

rials, set up the necessary redundan-

cies or implement mitigation mea-

sures so that the system can be

quickly recovered if it fails,” said

Postma. “ou only have a moment

during the six to seven years turn

around to check if everything is ne.”

Special attention was paid to the

variable frequency drives and the

throughout industries. Countries and

businesses have already been shifting

towards wind and solar in the EU, not

only to combat climate change but

also to safeguard themselves in a

precarious gas market.

Postma noted: “The difference in

price between electricity and gas has

now become more in favour of elec-

tricity. On top of that, there are decar-

bonisation goals. These are for many

of our customers, the two main drivers

to change from steam to electricity

for compression. CO

2

reduction is

of course important but the cost re-

duction in industrial processes justi-

es projects like this even more.”

There will be other benets from the

project too. In addition to cutting

CO

2

, electrication of the compres-

sion process also reduces energy

consumption by approximateky 75

per cent and notably nitrous oxides

(NOx) by 30 per cent.

Albert uyderduyn, Siemens Ener-

gy’s Project Manager for the Mo-

erdijk project, said: “NOx is arguably

even more important than CO

2

. And

there will also be a signicant reduc-

tion in the particulates emissions that

you have with gas, as well as im-

provements to further reduce the heat

loss so less cooling water will be

needed. After this retrot, it will be-

come one of the most efcient liquid

crackers in Europe in terms of energy

efciency.”

The project will be challenging. The

Moerdijk chemical complex consists

E-House with variable

frequency drive, cooling

system and auxiliary systems

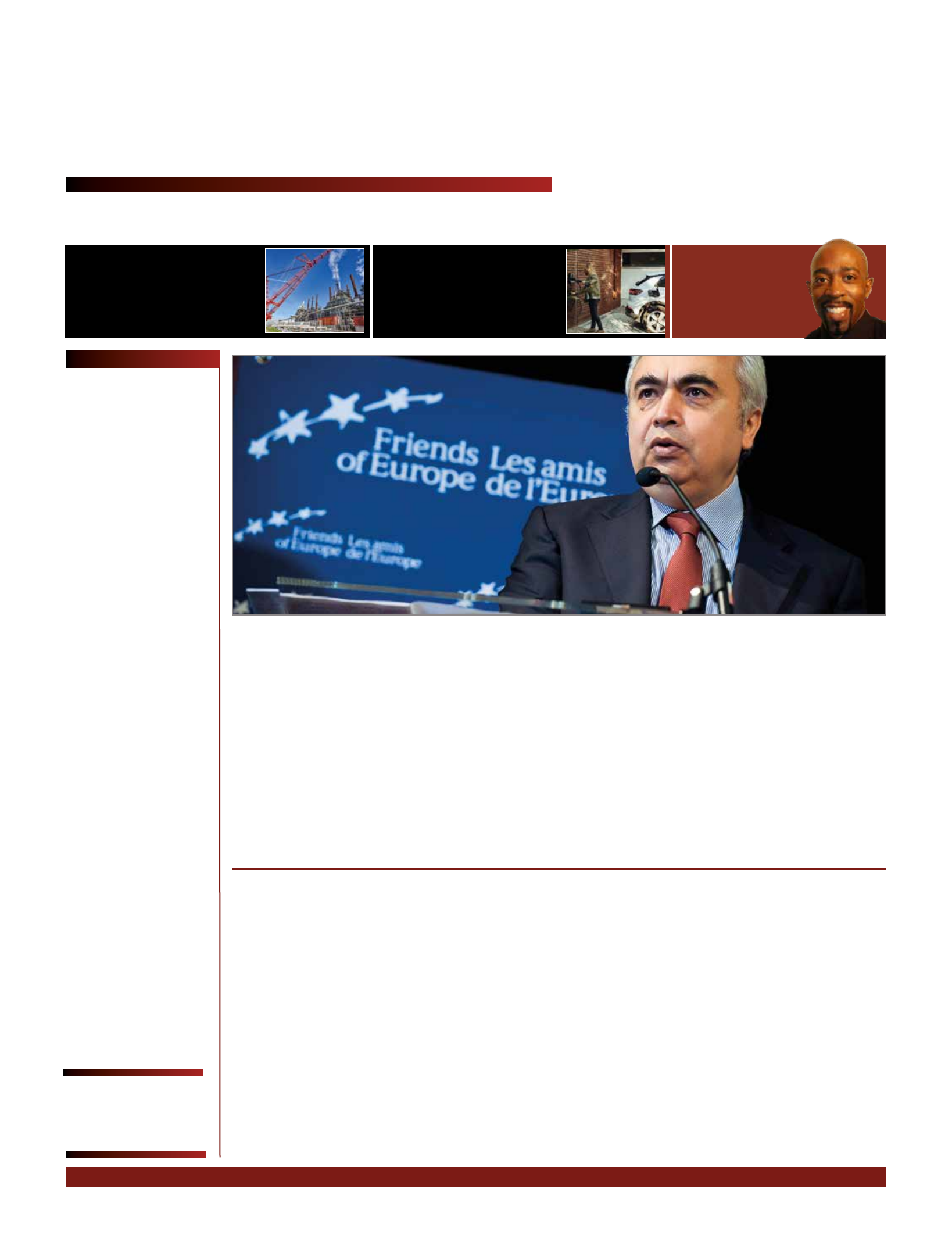

S

hell Chemicals Park Moerdijk

plays an important role in Shell’s

global chemical activities. o-

cated in North Brabant, Netherlands,

the complex has been producing

chemicals since the 1970s. But like

many other industrial facilities, Shell

has been striving to meet government

targets for reducing carbon dioxide

(CO

2

) emissions.

The most recent sustainability driv-

en project has seen Shell Chemicals

Park Moerdijk embark on a project

that will deliver signicant savings in

carbon emissions. In short, the project

will see the electrication of the

steam cracker process for producing

ethylene which is used as a feedstock

for the production of industrial

chemicals, a range of materials such

as plastics and food ripening process.

The project will see Siemens Energy

replace existing steam turbines driv-

ing compressors in the steam cracker

plant with electric drives in a move

that is expected to reduce Shell’s CO

2

emissions in Moerdijk by 230 kilo-

tons per year. At this scale, it could

become an industry showcase project.

Electrication has been on Shell’s

agenda for some time. It began at the

Moerdijk facility in 2018 with the

replacement of steam turbines with

electric motors at a non-critical ser-

vices part of the plant. The energy

transition journey continued with a

large solar panel park and replace-

ment of more efcient cracking fur-

naces with project Skyline. The latest

project, however, will see the electri-

cation of the core part of the chemi-

cal complex.

Peter Postma, Sales Manager, En-

ergy Solutions, at Siemens Energy,

has long been involved with the Mo-

erdijk electrication project and was

responsible for securing the contract

with Shell. He said: “The heart of the

Shell Moerdijk plant is the production

of base chemicals in the cracker with

ethylene and propylene as key prod-

ucts. The compression system is at the

heart of this production process. And

if it does not run, the whole plant

stops, resulting in aring and produc-

tion loss. So, the system must be ro-

bust. Steam turbines have therefore

been used since the 1970s to drive

mechanical compressors. These

steam turbines are driven by steam

from simple gas red boilers. It’s a

simple system that is still running to-

day; it is old but reliable.”

Using this simple but robust set-up

for compression made perfect sense.

In the 1970s there was no legislative

pressure to reduce CO

2

emissions,

and gas prices were low. Today, the

scenario is very different. Organisa-

tions and governments are under

pressure to become carbon neutral

within the space of just a few decades.

At the same time gas is now very ex-

pensive.

Extremely high and volatile gas

prices across Europe over the last

three years have certainly served as a

catalyst in the drive for electrication

Electrication nds a

sweet spot at Moerdijk

Special Project Supplement

THE ENERG INDUSTR TIMES - APRI 2025

Electrication of inustrial processes is seen as an important tool in the global ecarbonisation effort. Junior Isles

hears ho iemens Energy is helping hell to cut carbon emissions by replacing ol steamriven compressors

ith electric rives at the oeri hemicals ar in the etherlans.

Photo: courtesy Shell

Chemicals Park Moerdijk

8

THE ENERGY INDUSTRY TIMES - APRIL 2025

Special Project Supplement

High speed electric motor

with intermediate base frame

connected to the existing

compressor

Shell Chemicals Park

Moerdijk, located in North

Brabant, Netherlands, has

been producing chemicals

since the 1970s. Photo:

courtesy Shell Chemicals Park

Moerdijk

“The second important criterion for

the complete drive system is main-

tainability. If there is a failure, it must

be returned to service very quickly,

within hours. High system efciency

and pro-active monitoring is also very

important.”

As this is a browneld project, it

was paramount that Siemens Energy

paid close attention to space optimisa-

tion.

“The solution must be suitable for

the existing space and foundation.

Usually, the steam turbine has

smaller space requirements than an

electrical drive. So, you need to use

a specially designed high-speed mo-

tor to avoid the need for a gearbox.

We therefore selected products that

both we and Shell are familiar with,”

said Tomic. “It hits the sweet spot in

terms of reliability and sizing.” He

added: “Space also has to be opti-

mised for other areas such as the

substation and transformer.”

Siemens Energy is well positioned

to meet the numerous requirements of

the project. It is one of the largest

suppliers of rotating electric equip-

ment itself, and not only has advanced

tools for equipment design but also

for checking complete system integ-

rity, according to Tomic.

“As a leading company in the eld

of electrical engineering and inte-

grated projects in the power industry

as well as oil and gas, we can provide

complete solutions from high voltage

down to the motor. Siemens Energy is

one of the leading system integrators

for control and automation systems

for these drives,” he said. “Further,

we have a huge database [with data

and experience from similar projects

as well as from compressors and

electrical drives themselves, so we

are able to avoid potential weak

points.”

While this was one key factor in

winning the contract, Siemens Energy

also had to convince Shell that it

could execute it “awlessly”.

Postma explained: “During a turn-

around, when the plant is fully down

the turbine-motor swap will be done

with lots of preparation in advance. It

will be like open-heart surgery where

you have to do everything in time. So,

when the plant is shut down, together

with our partners, we must remove

the existing equipment and replace it

with the new equipment during this

period. So, it all must be perfectly

planned before we execute. This

means you have to put a lot of effort

into investigating and engineering so

that everything is done correctly.”

To ensure it is all completed in this

turnaround window, a number of ac-

tivities will be carried out in advance.

Initially it was planned that both

compression trains would be replaced

at the same time, but it was then de-

cided that the smaller train will be

replaced rst.

“As the smaller train is less critical

it is possible to continue production,

but just at a lower rate,” said Postma.

“If you switch off the smaller com-

pressor, you will just turn down the

total production volume. This means

the smaller train can be done without

stopping the entire process. So, it’s

like a pre-turnaround activity. And

the advantage of this is that we can

learn lessons to improve the second,

most important one that needs to be

done in the turnaround period. We

have experience with this, but every

project has its own characteristics.”

“Everything we can do pre-turn-

around, such as installation of certain

equipment, we will do pre-turn-

around,” added Zuyderduyn. “The

turnaround then includes decommis-

sioning the old steam turbine, remov-

ing it, installing the electrical motor

and connecting it to the compressor.”

The trickiest part will be the rst

startup. “You have to make sure ev-

erything is right”, says Zuyderduyn.

Everything has to be double-checked

and thought through in advance.

Siemens Energy is currently nalis-

ing the engineering. Zuyderduyn

commented: “We are focusing on the

production [of the equipment]. Then

for the middle of this year we will

start rst installations on site. And

then early 2026 is the big turnaround.”

This called for equipment to be or-

dered at an early stage, so that all

equipment is scheduled for delivery

this year. “It is our key focus that

these deliveries do not slip,” said

Zuyderduyn.

Although there will be several

milestones along the way, the key

dates are those for the turnaround –

early 2026 for the smaller 8 MW

compressor train, and a few months

later for the main 25 MW train.

On completion, the Moerdijk proj-

ect will provide a number of addi-

tional benets to Shell, in addition to

environmental and cost reduction.

Firstly, greater digitalisation will be

possible since all systems will be

electronic. “There is a goal to have

data analytics across the entire sys-

tem, so we can analyse the availabil-

ity,” said Postma. “With mechanical

drives, that’s not possible.”

“We are working on solutions to

predict and see degradation of elec-

tronics and then turn that into a pre-

diction of availability or the right

moment to replace it,” said Postma.

He also noted that greater digitalisa-

tion reduces costs.

As decarbonisation efforts continue,

Siemens Energy expects to see more

electrication projects within the

petrochemicals and oil and gas sec-

tors, especially in Europe. “Gas mol-

ecules will be replaced with green

electrons from renewables. And the

faster you can do this, the sooner you

will have sustainable productions,”

said Postma. “There are several pro-

cesses that can’t be electried, and

there you will use hydrogen. But to-

day, this electrication is the sweet

spot for CO

2

reduction.”

Accordingly, Siemens Energy is

gearing up for the surge in electri-

cation. “You see this in our compe-

tence centre, with new people joining

every month,” said Zuyderduyn.

Looking to the future, Postma

summed up: “There is a market here.

Customers are switching from gas to

electricity, which means they need

solutions like this. It’s a huge invest-

ment for Shell but the payback time is

only a few years. Sustainable solu-

tions cost money, but they pay-off in

the long run. This is a protable, sus-

tainable solution.”

cooling systems. The drives are

therefore equipped with totally re-

dundant cooling systems. All the

control systems that control the cool-

ing systems and drives are also con-

gured to be fault tolerant.

The RAM studies also demonstrate

how the solution will be implemented.

“Now the project still has to be deliv-

ered… the proof is in the pudding,”

said Postma.

Mitar Tomic, who is working as

Solutions Architect at Siemens Ener-

gy’s Centre of Competence for E-

Drives, has been involved since the

bidding stage, specifying the solu-

tions and technical scope of the offer.

He said: “We studied their situation

and made sure that the solution is reli-

able. We did a lot of work in selecting

equipment and assessing the various

solutions to translate that into avail-

ability gures; and then demonstrate

that it will work.”

Tomic added: “Unlike other indus-

tries, such as steel or mining, where

you have the opportunity to stop the

process every month or six months,

petrochemicals plants must run

continuously because any unplanned

shutdown results in production

losses and therefore nancial losses.

So, the key requirements for the

electric drive system are reliability

and availability.

9