H

ydrogen (H

2

) has become a

focus of energy transition

conversations for good rea-

son; when used it does not directly

produce carbon dioxide emissions.

This has created a buzz around the

element. As with past energy system

transitions, broad implementation of

methods to capture, transport, and

use hydrogen will require education

and expanded demonstration to ac-

celerate implementation.

Further improvements to tech-

niques and cost structures will need

investment, but the economic prize

for implementing large improve-

ments is enormous. Early imple-

menters of the best improvements

can obtain signicant market share.

The historically higher cost to pro-

duce hydrogen compared to natural

gas, however, has caused reluctance

to adopt this clean energy vector de-

spite millions of deaths globally per

year from air pollution. Though it is

the most abundant element in the

universe, the primary complication

is that hydrogen must be energeti-

cally separated from other com-

pounds like water (H

2

O) through

concentrated inputs of other re-

sources. Thus, current large-scale

hydrogen production methods are

costly, complex, and often reliant on

carbon intensive processes.

In 2015 while working as a geolo-

gist, alongside Dr. Ian Gates, who

was at the time the Department

Head of the Petroleum and Chemi-

cal Engineering Faculty at the Uni-

versity of Calgary, we realised an

opportunity existed to patent and

commercialise a new hydrogen pro-

duction method. Patents, simula-

tions, lab demonstrations and eld

demonstrations soon followed, and

in 2016 Proton Technologies was

created to proliferate the production

of clean, low-cost hydrogen from

oilelds, leaving not only the origi-

nal carbon behind, but extra carbon.

Coined ‘Clear H

2

’, Proton’s pro-

cess is signicantly dened in its

ability to be a carbon-negative pro-

cess. Clear hydrogen comes from a

process that can sequester signi-

cant external sources of CO

2

as car-

bonate rock, from direct air capture

for example. This is important be-

cause without some energy sources

having a carbon intensity below

zero, there is no possible way for

future energy systems to achieve net

zero. The ability to sequester and

negate emissions can create a price

premium for clear hydrogen derived

products like electricity, steel, am-

monia, synthetic fuels, and glass.

Proton’s process leverages previ-

ously expensed infrastructure. Most

big old oilelds are near existing

roads, power lines, pipelines, and

even towns full of skilled trades

who can directly transition to clear

hydrogen production. Rather than

spending a fortune to abandon tril-

lions of dollars in infrastructure

built up over the last century, exist-

ing energy infrastructure can be re-

purposed for clean, low cost energy,

thereby removing any requirement

for new ecological disturbances or

fresh water.

When oilelds are abandoned,

they still are generally more than

half-full, but the remaining oil is not

extracted due to commercial or

technical constraints. The remaining

hydrocarbons are Proton’s fuel sup-

ply, and the pore space within the

oileld is the reaction vessel – be-

low the geological seal which is the

reason the oil deposit accumulated

there in the rst place. Proton’s pro-

cess includes injecting oxygen, and

optionally CO

2

, into a well-bore

which triggers hydrogen-liberating

reactions. The resulting hydrogen is

separated and kept, and the carbon

is locked as solid carbonate within

the pore space of the oil eld.

The reactions within the reservoir

might be rst conceptualised as a

spherical zone where at the centre

partial oxidation reactions occur; and

in various temperature and composi-

tion rinds beyond there are many

other reactions: water gas shift, gas-

ication, aquathermalysis, pyrolysis,

reverse methanation, carbonate cre-

ation, and myriad others. The injec-

tion process is cyclic, and convec-

tion, buoyancy and concentration

gradient all play roles in the hot,

complex chemical dance. In short

and on a net basis, CO

2

and O

2

go

into the system, and H

2

comes out.

The process has been tested at

Proton’s own oil eld in Saskatche-

wan, Canada. The facility was con-

structed in 2011 at a cost exceeding

CAD$250 million ($195 million),

and by 2017 it was shut in and Pro-

ton was the fth owner. It was con-

nected to the electricity grid and

Proton plans to divert some of its

hydrogen to supply electricity to the

power grid through its 20-year con-

tract with the local utility. Baseload

electricity can be very low cost and

clean since hydrogen can be made

at lower cost than natural gas per

unit of energy.

First a turbine uses a small portion

of the produced hydrogen to power

a cryogenic air separation unit.

When air is cooled below -180°C,

the oxygen becomes a liquid. This

high purity liquid oxygen can be

separated, and warmed; which in-

creases its pressure. This highly

pressured oxygen can use the ventu-

ri effect to pull in additional CO

2

upstream of the injection wells. The

combined gases must only exceed

the reservoir pressure to be injected.

Some of the injected CO

2

can be

self-sourced and frozen directly out

of the produced gas stream, and

some of it can be externally sourced

in order to get below zero on carbon

intensity of the produced hydrogen.

The air separation unit also provides

nitrogen, which can be used to

make NH

3

(ammonia). Having all

the cold uids around opens further

doors; like data centre cooling, or

passively pre-chilling hydrogen

down toward -180°C so that further

temperature reduction to make sub-

cooled liquid hydrogen is only a

modest energy step.

These factors all enable cost struc-

tures that are attractive. Generally,

clean hydrogen is assumed to cost

more than $1/kg in long-range fore-

casts that include signicant econo-

my of scale and improvements. Pro-

ton believes that for large projects,

it can get into a levelised cost range

below $0.50/kg right away, and

with signicant likely further cost

savings. This makes hydrogen

roughly competitive with the cost of

natural gas per unit of energy; and

in districts where carbon taxes exist,

the advantages of hydrogen fuel are

even more pronounced.

Proton believes that roughly 10

per cent of western Canada’s hydro-

carbon resources can supply 10 per

cent of the world’s energy supply

for 50 years. A region with low cost

clean electricity and fuel at large

scale can provide signicant bene-

ts to other energy intensive busi-

nesses, enabling a new, clean, com-

petitive industrial ecosystem.

Proton Technologies is ‘clearly’ a

thought leader in the transition to

clean energy. While the company

currently has one operational facili-

ty in Western Canada, it has begun a

licensing programme that now in-

cludes clients across Europe, Pacic

Asia, and the Middle East. Licens-

ees can use their own sites to pro-

duce H

2

using Proton’s process.

Clear hydrogen, or carbon-nega-

tive hydrogen, will become a criti-

cal component of the global move-

ment to decarbonise the energy

industry by turning oil and gas re-

sources and infrastructure into

sources of clean, low-cost energy.

Whether it is used in turbines that

provide baseload power to the elec-

tric grid for electric vehicles and ap-

pliances, or whether the hydrogen is

directly used by fuel cells or heavy

industry, clear hydrogen is expected

to proliferate globally, rapidly.

Transitioning to “clean” energy

sources will forever create a certain

level of bipartisan jargon, with stake-

holders on either side struggling for

authority. Clear hydrogen is not only

an opportunity to produce low-cost,

clean energy, it is also an opportunity

for compromise and cooperation on

the idea that our world can improve,

and we should embrace that im-

provement, together.

Grant Strem is Chairman & CEO of

Proton Technologies.

THE ENERGY INDUSTRY TIMES - DECEMBER 2021

15

Technology Focus

A process has been

developed and

eld-tested, which

enables hydrogen

to be produced

from abandoned oil

wells at a cost that

makes it immediately

competitive with

natural gas per unit

of energy. Proton

Technologies’

Grant Strem,

explains.

The ‘clear’ path to low cost

The ‘clear’ path to low cost

zero emissions hydrogen

zero emissions hydrogen

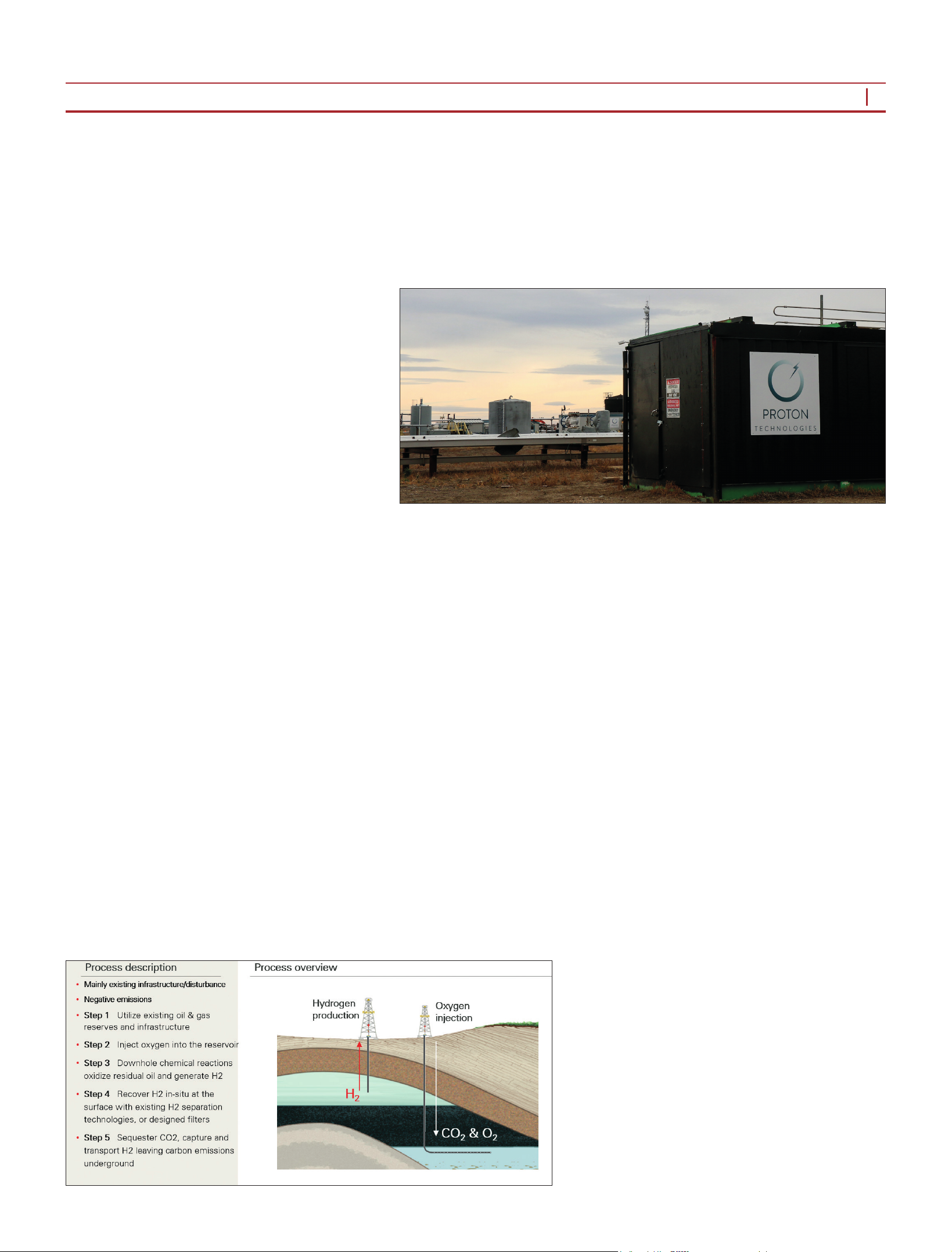

Proton’s rst asset is a test eld in Kerrobert, Saskatchewan, Canada. Proton plans to divert

some of its hydrogen to supply electricity to the power grid

Proton’s unique hydrogen

production approach