THE ENERGY INDUSTRY TIMES - SEPTEMBER 2021

Special Technology Supplement

Industrial gas turbines:

the perfect complement for

renewables-plus-storage

With the growth in

variable renewables,

energy storage is

expected to be the

key technology

for providing grid

support and shifting

renewable power to

when it’s needed.

Siemens Energy’s

Anders Stuxberg

explains to

TEI Times why

industrial gas

turbines will

be crucial in

complementing

renewables-plus-

storage in an

optimised system.

Junior Isles

prices for nal consumers, and the use

of smart meters.

“When you look at the demand for

balancing power, storage solutions

are efcient systems, with up to 80

per cent of the energy coming back

[from the storage]. But it is not eco-

nomical to design an energy storage

system for all possible situations. And

when you empty the storage, you

have to ll-in with something else,”

said Stuxberg.

That “something else”, he says, will

typically be (fuel red) thermal

plants, i.e. the backup power capacity

that must exist in the grid anyway to

ensure reliable supply when there is

no wind or solar for a long period.

There are several options as to

which technology, or group of tech-

nologies, can support renewables-

plus-storage depending on the sce-

nario. For example, arguments are

sometimes made for fuel cells while

other experts present compelling

cases for fast-start generating assets

such as gas turbines and reciprocating

engines.

Stuxberg believes industrial gas

turbines are currently the best all-

round option. He commented: “In a

deeply decarbonised energy system,

gas turbines will play a key role both

for mid-merit power supply and as

backup power. Although some argue

that fuel cells will take that role, that

can only happen if fuel cells for a

fully functional and installed power

generation plant become cheaper than

gas turbines. We are not there today

and I believe that if it happens, it will

take many decades. Fuel cells,

though, are already a good option for

microgrids and mobility applications.

The requirement that backup power

also should be fuel exible, e.g. use

both hydrogen and liquid renewable

W

ith the urgent need to combat

climate change, wind and

solar power are growing at a

phenomenal rate. According to the

International Energy Agency, renew-

ables will meet 80 per cent of global

electricity demand growth during the

next decade. Solar PV, for example,

dubbed by the IEA as “the new king”

of electricity supply, grows by an

average of 13 per cent per year between

2020 and 2030, meeting almost one-

third of electricity demand growth

over the period.

The variable nature of wind and

solar, however, presents challenges in

terms of grid stability and how best to

provide backup power for when the

wind is not blowing or the sun is not

shining.

With targets set for reaching zero

carbon emissions in the electricity

sector, clearly the goal must be to

support renewables as far as possible

with energy storage – a zero carbon

source of grid exibility. The ques-

tion, however, is what generating as-

sets to deploy alongside storage, and

how to achieve the best mix of storage

and those assets in terms of cost and

operability.

Anders Stuxberg, Specialist in

Power Plant Process Integration at

Siemens Energy AB said: “Gas tur-

bines (GTs) will be the technology of

choice to be dispatched when storage

power capacities are insufcient for

the demand and also when the storage

becomes emptied. If you look at bal-

ancing supply and demand through

the grid in general, you have to look

at it over a number of different time-

frames. The system has to be man-

aged, second-by-second, minute-by-

minute, hour-by-hour, using different

technologies. You also have to look at

balancing over longer timeframes…

The question is how to optimise these

storage and generating resources.

Storage will handle the bulk of energy

for balancing, but there will not be a

business case to try to cover every-

thing with storage alone, you will

need to complement it with GTs.

“By implementing storage, the op-

erating prole for GT-based plants

will be signicantly changed. GTs

will be a cornerstone of the grid infra-

structure but with a new role in future

compared to what we have been used

to seeing. You will see a shift to

backup power instead of peaking

units and exible mid-merit com-

bined cycle plants instead of baseload

plants; this will favour industrial GTs

for new installations. Industrial gas

turbines are also suited to use hydro-

gen as fuel and fuels produced

through power-to-X schemes,” said

Stuxberg.

With storage expected to take cen-

tre-stage in maximising the integra-

tion of renewables and distributed

generating sources, the market for

the technology is forecasted to grow

exponentially over the next decade

(see box).

Regardless of which of the various

storage solutions is selected, however,

they are all generally limited by two

parameters: power capacity and en-

ergy capacity, i.e. duration of storage

at full power. Stuxberg noted that

when optimising storage solutions,

power plant owners will size for the

most frequent instances that give the

most energy trade volume and then

leave the residual load to some other

technology.

He said: “There will be many days

the energy in the storage is insufcient

for the demand and many days when

storage systems have less power ca-

pacity than needed, at least during

part of the dispatch duration. So other

technologies will be called for both at

surge of power and of energy, there

will be a play between different types

of storage solutions and capacity

backup.”

He also noted: “Storage technolo-

gies that can shift operating mode af-

ter the storage is emptied – continuing

power production by ring a supple-

mentary fuel – will also play a role in

backup supply, i.e. double benets to

the system. Examples are: power-to-

hydrogen-to-power where the hydro-

gen-to power unit (gas turbine) oper-

ates on e-methanol when the gas

storage is emptied, or a thermal stor-

age plant that also can run by ring of

e-ammonia when the thermal storage

is emptied.”

Stuxberg says there will also be

competition between storage and

demand response (DR). If altering

the time of energy use (e.g. smart

charging electric cars) does not dam-

age business, then DR will be more

efcient and cost competitive than

storage.

Many types of DR will, however, be

limited in much the same way as stor-

age. For example, duration – mainly

limited by the nature of the demand

that has been put on hold – will nor-

mally be limited to a number of hours.

The amount of DR that will be avail-

able naturally depends on the price

incentive, the volatility of energy

Power plant owners will optimise storage solutions size for the most frequent instances that give

the most energy trade volume and leave the residual load to another technology

Don’t let balancing power capacity get out of balance

Storage will handle the bulk of energy for balancing but it will

need to be complemented with GTs

slightly more expensive power than

the storage system. If the dispatch is

just based on a commercial energy

trade, then hybrid plants comprising a

combination of e.g. renewable power,

storage and GT may be a good busi-

ness as smarter dispatch can be

achieved.”

Typically, many gas turbines will be

installed in an electric grid to provide

the necessary backup power. The

dispatch order for these will be based

on cost or environmental footprint.

Since the requirement will be for a

fairly low dispatch rate, Stuxberg

says a large portion of dispatch may

be based on capacity auctions where

a xed compensation for just existing

as available backup is paid out.

If efciency is also credited, e.g. by

dispatch order, then a fair portion of

these cycling GTs will be congured

as combined cycle. However, the

bottoming steam cycle must then be

suited to frequent starts, i.e. fast and

with low start-up cost. Stuxberg notes

that in a future where these mid-merit

plants need to operate on renewable

fuel, which will be expensive, a bot-

toming cycle will be required for

many of these plants for the sake of

opex. The remaining plants, which

will have a low dispatch rate of, say,

less than 500 hours per year, will not

be so sensitive to efciency but will

need to have low capex and xed

standstill cost.

“So, for the power generation busi-

ness, we will see two typical types of

GT plants for the future: combined

cycle plants for cycling operation,

dispatching in a mid-merit pattern of

somewhere between 1000 and 3000

hours per year; and simple cycle

plants, with dispatch often less than

500 hours per year. The traditional

base load plant is thus replaced by a

very exible mid-merit plant, while

the traditional peaking plant is re-

placed by demand response and stor-

age solutions plus a large quantity of

backup power.”

His absolute conviction is that in-

dustrial gas turbines present the best

suitability to this type of future duty

for both these plant types. “They have

very high reliability due to simplicity

in design concept, high combined

cycle efciency, low price, low main-

tenance cost, good fuel exibility and

much better grid stabilisation charac-

teristics (by high inertia and strong

control response) than aeroderivative

GTs or recip engines,” he said.

For both these plant types, his ex-

pectation is that there will be an aver-

age of one start every one to four

days, most frequent for the mid-merit

type. Stuxberg predicts a wide operat-

ing regime for such gas turbine plants.

For demand response (DR) and for

energy storage systems, he noted that

they will dominate dispatch of bal-

ancing power for short duration and

during periods of low demand for re-

sidual power.

He noted, however: “When looking

at capacity it is hard to rule out rare

events with low probability, thus in-

stalled GT power capacity in the grid

will need to be large. The scale of

backup capacity needed depends

predominantly on the capacity factor

fuel is also a cost issue, if not a prob-

lem, for fuel cell plants.

“Reciprocating engines compared

with gas turbines have pros and cons.

In short, they are less efcient than

combined cycles and are more expen-

sive per capacity than simple cycle

GTs, with the exception of emergency

diesels gensets, which have a shorter

lifespan. For mid-merit operation,

maintenance cost is an important

factor to consider – industrial GTs

have lower maintenance cost than,

e.g. recip engines or fuel cells.”

He also notes that conventional

boilers with steam plants are too in-

exible to handle the frequent starts

and stops to balance residual power

demand. Further, their efciency is

low, especially if designed for renew-

able fuels such as biomass.

Based on the shortcomings of these

technologies, Stuxberg believes the

focus for grid balancing should there-

fore be on a blend of industrial gas

turbines (IGTs) and storage solutions

and a probable future dispatch prole

for those assets.

IGTs in the range up to 70 MW are

typically used in a number of applica-

tions. CHP applications are common

across the whole range due to their

ability to meet heat demand. The

smaller machines may be deployed in

settings like hospitals, universities,

small industries and O&G, to provide

power in areas where the grid is not

completely stable or onsite generation

is required. Medium-sized machines

in the upper range of 30-70 MW may

be used by, independent power pro-

ducers (IPPs), industrial CHP asset

owners, the O&G industry, munici-

palities producing electrical power

for the grid and heat for district heat-

ing networks, as well as utilities.

Stuxberg believes the operating

prole of IGTs in the future will not

be same as the peaking units of today.

Units in the future he says might start-

up and shut down once a day during

parts of the year, be in standby other

periods and also occasionally run for

a longer period, as opposed to cycling

several times per day.

With storage expected to be the rst

option for supplying multiple daily

power peaks, operators must then

decide how gas turbines will operate

to complement this storage.

Stuxberg foresees gas turbines be-

ing dispatched when the energy re-

quired exceeds what is available in

the storage. This will likely be after

the large afternoon/early night peak

or possibly in the morning. Gas tur-

bines will also be called for when all

storage solutions are already provid-

ing near full power capacity, i.e. typi-

cally during the evening peak.

He explained: “If GTs are being

called on every day for one of the two

reasons, power surge or energy surge,

then that’s a signal to storage inves-

tors that here you have an attractive

business opportunity – just buy some

more capacity. It’s low-hanging fruit.

So my conclusion is that GTs will

typically start once every 2-4 days on

average; some days they might be

called on twice and many other days

not at all.

“Traditional peaking plants and

base load plants will no longer be

suitable for this kind of market. So if

we have a GT on the system to ensure

backup anyway, the question is:

should you operate it for more hours,

which means more fuel consumption,

or should you make the storage

slightly bigger?”

According to Stuxberg, that optimi-

sation determines how the gas turbine

is operated, the type of turbine se-

lected and whether the plant should

be simple cycle or combined cycle.

He explained: “Generally, each ad-

dition of duration for a storage tech-

nology comes at an added investment,

which needs to be paid for by less and

less events since long duration events

are less frequent than shorter events.

The marginal cost of longer operation

for a GT plant ring renewable fuel

on the other hand is constant as it just

adds fuel consumption (fuel storage is

relatively cheap). The duration at the

cross-over point between technolo-

gies depends on event probability, a

number of economic factors and

choice of technology. The decreasing

probability of long events explains

why even pumped hydro plants, at

present, often are sized to t just one

day cycles.”

He added: “Grid balancing of up to

a couple hundred megawatts would

be fairly common. This could be di-

vided across a number of machines so

you can follow demand better without

running machines at part-load.”

Such an installation would have to

be capable of meeting several require-

ments. Firstly, it should be capable of

starting “reasonably” fast.

“If there is some kind of communi-

cation protocol (using new IT solu-

tions and advanced forecasting tools)

in the market telling GT operators to

start in fair time before stored energy

runs out, then very fast GT start is not

required, 20 minutes should sufce,”

said Stuxberg. “Also when power

capacity becomes the issue, it should

on most occasions be possible to

predict when to dispatch GTs. How-

ever, power peaks come faster than

drainage of energy, so here dispatch

centres can reserve some power in the

storage by starting the GTs a bit in

advance when a demand ramp-up is

expected. Here a fast GT start pays off

a little as there is less need to reserve

power from storage dispatch and thus

there is a bit less operation of the GTs,

which could be assumed to produce

Special Technology Supplement

THE ENERGY INDUSTRY TIMES - SEPTEMBER 2021

IGTs such as the SGT-800 are

typically used in a number of

applications

The dispatch order for

GTs in the grid for backup

will be based on cost or

environmental footprint

Stuxberg: in a deeply decar-

bonised energy system, gas

turbines will play a key role

both for mid-merit power sup-

ply and as backup power

THE ENERGY INDUSTRY TIMES - SEPTEMBER 2021

through to morning and for the bal-

ancing duty that storage solutions

would otherwise provide, as there is

no surplus renewable power during

the day for charging the storage.

Here, high efciency storage is

charged from high efciency mid-

merit GT plants during the day, as

this limits the need of thermal plant

capacity during the peaks. The result

is that the required thermal plant ca-

pacity is about twice the capacity of

installed storage.

If DR is added, it would reduce the

required amount of storage as well as

the power capacity for storage charg-

ing/discharging during an average

wind day. In the low wind scenario, it

would also reduce the need for in-

stalled thermal capacity, as it attens

the thermal power supply.

“Naturally reality is more complex

than these simple scenarios, with sea-

sonal variations on both demand and

supply, effects of clouding, fast uc-

tuations, grid disturbances etc.,” noted

Stuxberg.

Fuel exibility also has to be a key

consideration. If a machine is oper-

ated for less than 1000 hours/year,

the impact of fuel consumption on

environment and economics is rela-

tively small. However, the goal is to

of wind and solar and level of long

distance power transmission. Up to

about 50 per cent of grid capacity may

be expected; in isolated grids or grids

with weak connection to other grids

one may even argue for 100 per cent.

When you also look at resilience and

tolerance for grid failures most of the

GT installations should be distributed

in the grid, this favours mid-sized gas

turbines as well as exible CHP. In

large, high capacity grids, large GTs

will also be attractive for backup

power capacity due to low specic

investment.

“When looking at energy supply

rather than the installed capacity, de-

mand response and storage will dis-

patch maybe 80 per cent of all energy

needed for grid balancing and GTs

only the remaining 20 per cent. Those

GTs should preferably operate on re-

newable fuel.” he added.

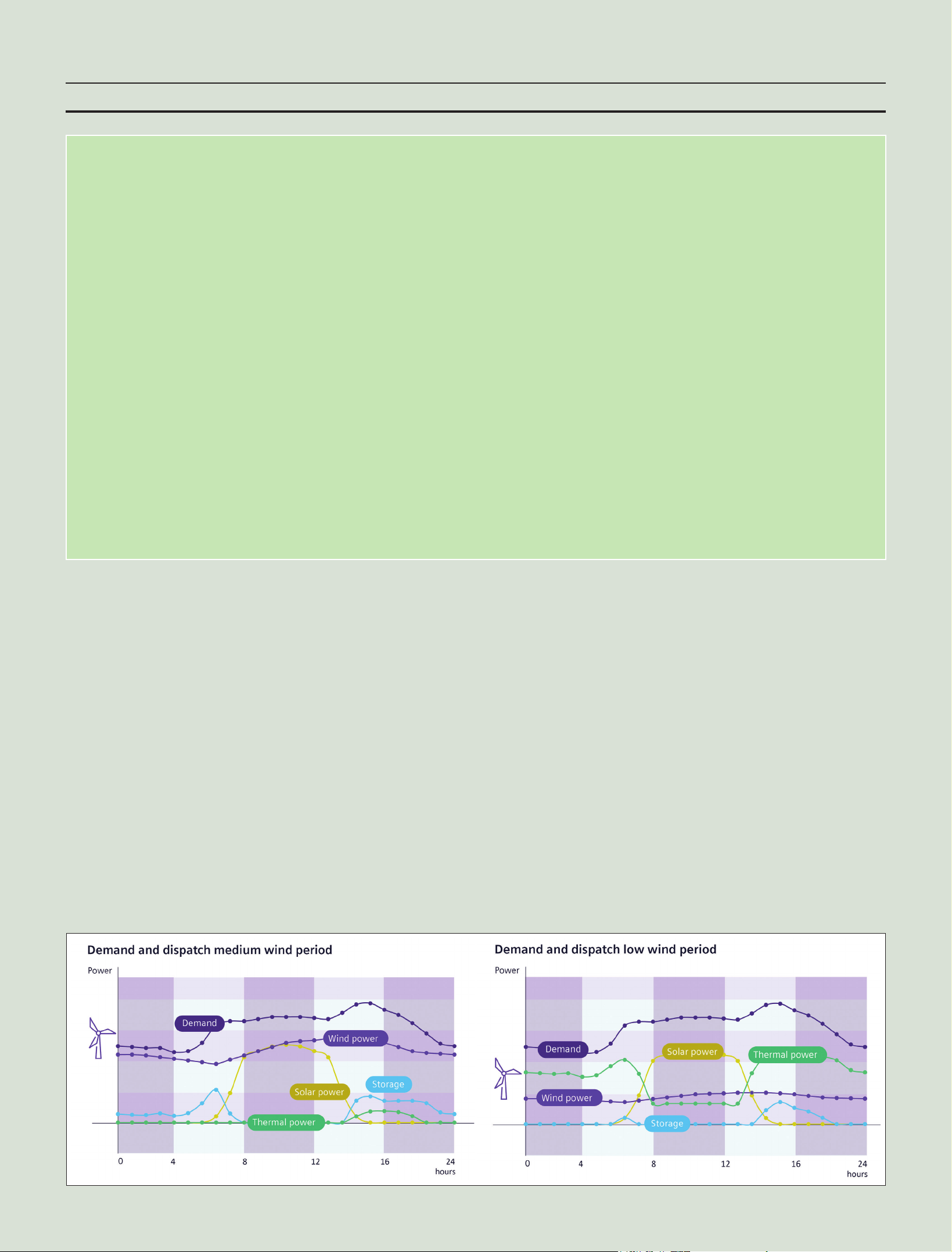

The gure below shows demand as

well as solar and wind supply in a

simplied ctitious medium size

grid. On the left, wind supply during

an average day, where energy fed into

storage covers about 85 per cent of

the balancing need. On the right,

where wind supply is low, thermal

power generation is needed to replace

lower wind supply during the evening

run turbines on renewable fuels, and

uncertain policy in the long-term out-

look in this area is a challenge.

Stuxberg said: “There are a number

of optional renewable fuels for use in

GTs, hydrogen being one of the top

candidates, but today we don’t know

which of these will be economical or

available in the future and obviously

it will always depend on the site loca-

tion and operating prole. But the

point is, industrial gas turbines are

exible”

The market for IGT-based grid

balancing assets is huge – anywhere

in the world where there is renew-

ables growth calling for day-to-day

renewables support, while offering

emergency backup for the grid.

There is also room for large frame

gas turbines, where countries have

large robust grids.

“In Sweden, we have a lot of hy-

dropower but when we close down

nuclear capacity and replace with

wind farms, there isn’t enough ca-

pacity to handle the residual power

peaks. There we will see a large de-

mand for [GT] backup power. Those

machines would probably operate

for less than 10 per cent of the time.

In many markets today, there is no

compensation for having capacity in

place and that is an issue.

“Grid integrity and resilience via

sufcient backup should mainly be

seen as part of the grid infrastructure

rather than energy trade. Solving

backup power supply with existing

coal red plants is a route that has

already proven a failure as it counter-

acts the greenhouse gas savings from

renewable power, i.e. incentives for

investment in more suitable backup

technology is needed” said Stuxberg.

He concluded: “Renewables and

storage systems will play the major

future role for energy supply but that

requires a lot of exible backup and

for that gas turbines are the most cost

effective today – if you need to build

capacity today; it’s gas turbines.

“We can only speculate on what

will happen in the future through

development of other technologies.

But we need to change the energy

system now. With the environmental

challenge, we cannot wait 30 years;

so we have to base it on the technol-

ogy we have today and industrial gas

turbines is an available technology

well t for the purpose. Backup

power also needs to be installed

ahead of renewable implementation

to ensure grid resilience, so the need

is urgent.”

Demand, solar and wind

supply in a simplied

ctitious medium size grid

Special Technology Supplement

The energy storage market is forecasted to grow exponentially

All storage technologies can store surplus renewable energy and return it to the

grid later, thus avoiding curtailment and increasing the use of renewable power.

According to analysis from IHS Markit, annual installations of energy storage

capacity globally will exceed 10 GW in 2021, more than doubling the 4.5 GW in-

crease in 2020. The existing capacity in stationary energy storage is dominated

by pumped-storage hydropower (PSH), but because of decreasing prices, new

projects are generally lithium-ion (Li-ion) batteries.

PSH capacity additions are predicted to remain constant at 5-10 GW per year,

while battery capacity is expected to grow from 2.3 GW/year in 2018 to above

30 GW/year in 2050. Total installed storage capacity was around 170 GW in

2019, a gure that is expected to reach 950 GW by 2050, according to IHS

Markit.

Another report – ‘The Energy Storage Grand Challenge Energy Storage Mar-

ket Report 2020’ – published by the US Department of Energy forecasts a 27

per cent compound annual growth rate (CAGR) for grid-related storage through

to 2030. It projects annual grid-related global employment to increase about 15

times from around 10 GWh in 2019 to almost 160 GWh in 2030.

The type of storage deployed will depend on grid design and the distribution

of generating plants and loads unique to each grid. The technology selected

depends on which offers the best economic and operational capability according

to the services, range of capacity and energy discharge duration needed.

Super-capacitors and rotating grid stabilisers (ywheels and synchronous

condensers) provide instantaneous system responses and grid control. Both

technologies are aimed at applications in the range of approximately 1-100 MW.

Pumped storage hydro is the most dominant energy storage solution in terms

of globally installed megawatt capacity, representing some 93 per cent of the

operating system. It is a gigawatt-scale technology mostly used for energy shifting

and high-capacity rming with storage durations of around days or weeks with mini-

mal energy losses.

Further, capacity and operating reserve is provided when the asset is connected to

the grid. But although a mature and widespread technology, its main drawback is the

required topology of the site (large height differences are needed) and its physical

impact on the environment.

Thermal energy storage (TES) can improve utilisation of waste heat, assist in the

electrication of process heat supply, or store renewable energy for re-electrication

using a steam turbine. TES can also be integrated with thermal generation plants,

e.g. a combined cycle plant. A wide variety of heat storage media are available,

including liquids such as molten salt and pressurised water, or solids such as stone,

steel, concrete, or sand.

Liquid air energy storage (LAES) and compressed air energy storage (CAES) are

further technologies aimed at gigawatt-scale applications. LAES is based on the

cryogenic liquefaction of air when it is compressed with the use of (preferably)

renewable electricity. The liquid and the produced heat can be easily stored and

discharged when needed for re-electrication. CAES works similar but stores com-

pressed air. By adding a thermal storage to this technology, the overall efciency is

improved.

Li-Ion batteries are currently the technology of choice driven by their cost-effective-

ness and speed characteristics. They offer several applications, such as frequency

response, exibility enhancements of conventional power generation assets, black

start capabilities or energy arbitrage. Their sweet spot is up to around 250 MW and 5

hours of duration.